-

Content Count

124 -

Joined

-

Last visited

Posts posted by Rewillia

-

-

2 hours ago, kaypsmith said:Rick, for future reference, those cheap remote controllers that you can order on ebay work really well for your type of project. You can find a hot 12 volt wire in many places on your coach, then install one or more of those critters almost anywhere. You can also power on or off all or only one at a time from a single remote. This is what I like most about, I carry the remote with me and use at any time.

The controller I installed came/comes with an RF remote. What you see in the photo is the RF paring device, re: controller that all the wires from the lights connect to. It, the controller then direct wires to a 12 vDC power source which as I mentioned with come from a spare 20-Amp fuse terminal on my 12vDC panel inside the electrical bay. (the white button on the face of the controller is for pairing it with the remote) and is not an on/off switch.

I purchased the Boogey Lights Under Glow set-up to include the 10-separate pre-wired led light strips in the lengths I wanted along with their HD-M7 RF controller, aluminum channel and diffuser panels. I will also be adding a separate switch to power the system on/off as an additional safeguard.

-

8 hours ago, manholt said:Rick. Great work and the drawing makes it easy to visualize! A separate 20A fuse is a good solution to Herman's statement! The biggest plus for you, is that when your finished with this "Project", you will know every square inch of you coach! Hope your taking lots of pictures for any future problems you might encounter under and over chassis.

Joe. Scroll up and you will come to Rick's post, where he say's that "unfortunately, schematics of wiring runs are not available from Newmar or Spartan"! That was yesterday at 3:30.

Photos attached. More to come now that the hurdle of getting wire run from the chassis battery compartment to a cargo bay ahead of the rear axles and wet tank bay compartment is completed.

-

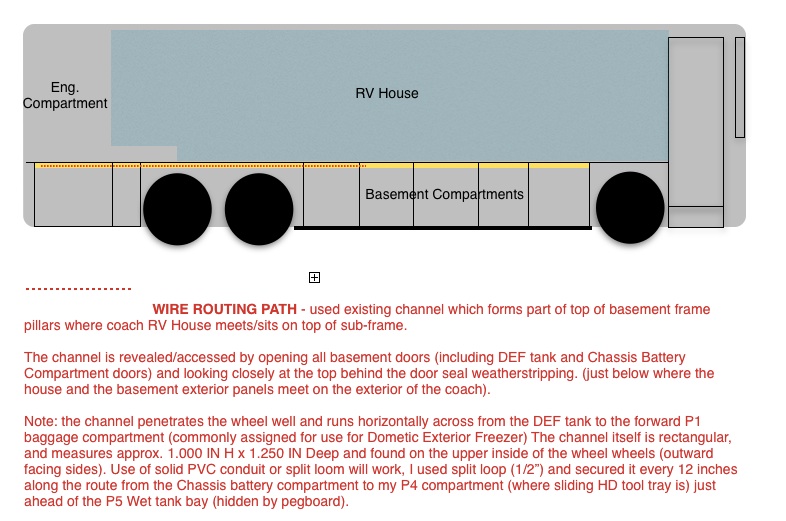

LENGTHY COMMENT - MEANT TO DESCRIBE LOCATION OF ACCESS CHANNEL FOR RUNNING WIRE FROM REAR (ENG) TO FORWARD BASEMENT.

As previously mentioned here, I've been struggling to find a means of access to run wiring from the rear of my coach, ( i.e. engine compartment) forward into my basement compartment ahead of the drive & tag axles as well as the wet bay (tank compartment). With the RV house, Frame Rails and Belly Pans fully sealed at the back (engine compartment) as well as underneath the coach forward of the drive axle, there was no "apparent" means of access to fish/run the additional wiring without penetrating either the RV house or the belly pans which I wanted to avoid for all the apparent reasons (as well, not to mention that practical reach to some of those areas is next to impossible). I had previously tried running a fishing tape at various locations from inside of the basement area (and exposed frame rails) back to the engine compartment with no success. It has been frustrating.

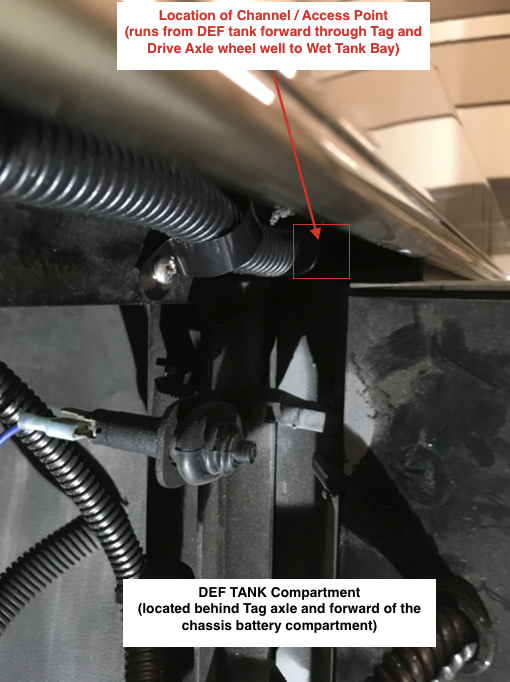

That said, I finally had some success yesterday after discovering a horizontal pathway on the passenger/door side of the coach located at the top of the basement doors (behind the weatherstripping that also includes a semi-closed section of metal channel that runs the length of the rear tag/drive axle wheel-well between the DEF tank compartment (aft of the Tag axle) and the wet tank bay (forward of the drive axle). The location of the channel or void space may be best referred to as an area that exist between the location where the RV house meets and sits upon the sub-frame (much to the like of what Rich referred to in his comment/post above).

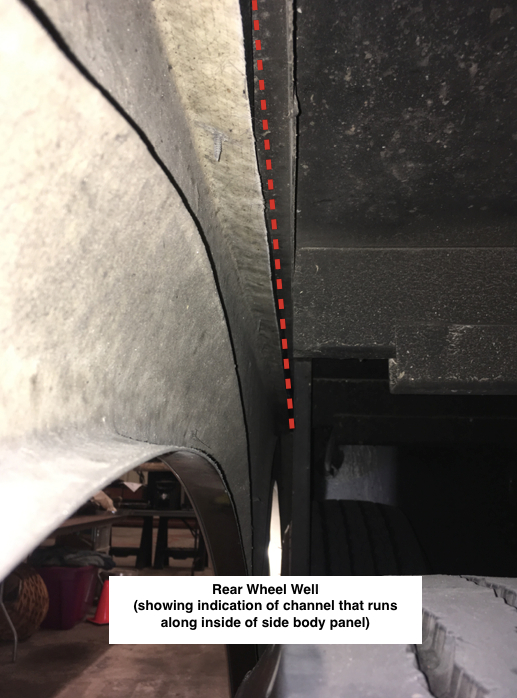

The pathway is hidden by either basement doors/frame work and it's weatherstripping or by the exterior painted fiberglass body side panel that cover the wheel well (between the forward and aft basement compartments). Using it, I was able to run a horizontal 20 ft. +/- section of 1/2" split loom flex conduit (and wiring) from my DEF tank bay forward to the basement storage compartment (ahead of the wet tank bay just ahead of the drive axle) and only had to drill one small 1/4" hole for my wire through the weatherstripping and vertical metal frame that host the basement door. I then further secured the split loom flex conduit ever 12 inches (including the exposed area inside of the well well) using conduit fasteners which serve to hold it taunt and in place. I plan to follow-up with using some expanding foam spray and undercoating on the exposed section of channel inside of the wheel well area to further secure and protect the wire loom.

Note: While choosing to use split loom flex conduit I could have equally used 1/2" PVC rigid conduit for the exposed section of channel inside of the wheel well area but fell that the split loom will be fine given the additional measures taken to secure it plus the fact that its semi-protected to begin with in that its laying at the bottom inside the channel which is all but closed other than having a 3/4" reveal at the top of it; Think U-shaped.

Power source. (reply to Herman's comment). In doing the installation of these LED under glow surround lights (10-separate light strips), they will be bridged using post terminal blocks at the front (genset slide), mid-ship (basement) and rear of the coach (chassis bat compartment) with each commonly grounded (-) to the chassis while the common power (+) source will be taken from a spare fuse block terminal inside my electrical/cord reel bay and using a 20-amp fuse. (location of power source recommended by Newmar). The LED Light RF Controller along with a separate power on/off switch will be mounted inside the passenger side basement compartment as to improve RF signal transfer vs. installing it in the driver's side cord reel bay.

I will be posting photographs in the coming days but for now am providing the sketches below which hopefully provide further explanation of where the channel or void space is located and hopefully assist others contemplating a similar installation of aftermarket LED surround lighting (at least on coaches of similar body style and design).

-

20 hours ago, DickandLois said:Rewillia,

I did some rewiring on our coach marker lights and used some 3/8 in. PVC with some 90, 45 and 30 degree fittings to construct a conduit. As I routed the conduit, I also passed the wire through it as each section was attached. Running wire through all the twists and turns when the whole run is assembled is just not doable.

Used clamps to hold the sections in place. Did not cement them, just pressed them tightly together. Keeps the wires protected, out of the way and looks very much like an OEM install. Sprayed the assembly with undercoating.

Never drilled a single hole for the conduit, just the ones needed to place the clamps. If needed one could drill a hole or 2 just big enough to run the PVC and then seal the gaps with some sealant.

Rich.

With your reference to marker lights, am I safe to assume you mean between the front and rear/drive axles. My challenge is to run the wire from my rear engine compartment to a location ahead of the drive axle and that's where it's gotten complicated. Other than in the engine compartment and rear axle area, My chassis is fully sealed underneath with belly pans so I have no means to access the frame members ahead of the drive axle (and I'm not prepared to start pulling belly pans off).

It may indeed come to something like that (routing under the chassis forward ahead of the rear axle ) but I'm going to take another "stab" at finding a way today. Unfortunately, schematics of wiring runs are not available from Newmar or Spartan so I'm left to my own creative means of tracing existing wire looms and using a fishing tape. What cautions me is the idea of running a lengthly metal fish tape into and through one of the existing conduits and getting stuck to a point that I have to exert more pressure than desired to retrieve it and end up pulling something apart (then leading to a much bigger problem). If I knew more about how the coach wire runs are laid particularly between the chassis and the house then It'd be easier but as it is now, I'm left to my own creative devices to find the right path.

Thanks to ALL here who have provided input on this subject to date.

-

I'm somewhat stuck now trying to sort our how to fish wire (16AWG) to the electrical cord reel bay from my engine bay. Can't seem to locate a conduit tunnel or opening that I can fish the wire through. Have tried using a powerful LED flashlight to beam light from inside the basement back toward the engine compartment but am yet to see any indication of the light penetration. Placed a call to Newmar Customer Service and their reply was to run it through the frame rails. Unfortunately, that "dog won't hunt" as my frame rails are sealed and where they penetrate the basement are as well sealed. I definitely do not want to run the wire under the coach and figure there's got to be a way to get it there through the basement.

-

After a brief delay, I have resumed my DIY installation of the soft white (single color only) Boogey-Lights Under-Glow LEDs on my coach this week and will share/post additional photos shortly. Having already completed installation of the lights underneath the front fascia, ahead of the front steer tires & door steps as well as behind the tag axle and across the rear (above rock guard), I'm currently running the aluminum channel extrusions between the front/steer and rear/drive axles and should commence connecting the wiring runs later this week.

Side channels are being attached to the underside of the belly pans using self tapping screws with small o-rings on the backside between the channel and belly pans as to form a good seal.

-

Have started my installation which will include the addition of 10-ten separate LED strips, one RF controller to be commonly switched taking power from a spare 20A fuse terminal in the coach electrical bay (cord reel bay).

Over the course of installation, I'll be posting photographs that will hopefully help other contemplating a similar "DIY" install of ground surround LED lighting underneath their motor home.

Here are some photos on the front fascia generator slide LED instal. As shown, I used 1/4" SS all thread (replacing the OE 1/4-self-tapping screws which anchor the fog light brackets) as the end mounts for some 3/4" W aluminum angle extrusion to which I bolted the LED aluminum channel to. Then added a center support bracket from my generator slide actuator housing making sure that when closing the LED light bar and support bracketry will clear all and it does. Since these photos were taken, I've installed 3' ft sections under the coach forward of the front steer axle (including under my hyd. entry steps), 6' ft sections behind the tag axle on both sides and an 8'ft section across the back above the rock guard. Had to suspend the project for the moment due to a family matter but once I get back to it in the coming week, I'll post additional photos.

LF - OEM Fog Light mount anchor brace used to anchor LED strip light aluminum extrusion and channel. 1/4" SS all thread secured with lock nuts.

View from LF to RF

View RF to LF. denotes use of 1" aluminum flat bar bolted to generator slide actuator/ram head bracket to serve as center support arm for LED aluminum extrusion and strip light channel.

-

Recently experienced a similar problem in the my dash AC would start by blowing cold air then turn warm after a period of driving. End result being I had a bad heater control valve up front on the generator slide bay that was not closing completely and allowing hot water to circulate hence defeating the efforts of the AC. Once replaced, the dash AC works as it should.

-

Jim S,

I agree, just pointing to the principle that using steam aids in the removal process. Also it's interesting to note in the video they recommended pulling it away from the surface opposite of the material vs. pulling up and peeling it back toward it.

-

-

I'm doing the complete ground effects surround on the underside of the MH in soft white LEDs that will match my existing and OE awning leds. Plan now is to use the aluminum channel and diffusers, install the 12vDC controller in the electrical bay and switched all tied into an existing spare fuse circuit on the distribution panel. The LEDs will be installed (using the channel) on the underside of the belly pans and thus, will not be visible from the side of the coach. They are also dimmable so we can use with discretion.

-

This post/thread is closed. All OP questions have since been answered/obtained from additional resources.

-

DBH,

What you describe is most certainly has been a "disservice" to you and I'm personally appalled at what you've been experiencing. It's less than poor, it's shameless that some manufacturers and their assigned dealers are not more responsive to THEIR customer's needs.

-

A Detailer's secret per say: Use steam to remove the clear bra, i.e. laundry steamer or some type that will give you a concentrated amount of steam (flow) through a nozzle and the clear bra will come off easily. Then you can use a wax & grease remover such as 3M to get any residue off. Using steam (carefully) will not damage the underlying paint finish.

Same applies for removing window tint - when using steam it will come off as an entire sheet and not break/tear apart leaving one with numerous fragments/strips to peal away. just heat it with the steam at one of the edges and slowly start to work it back and off of the surface.

-

I tend to appreciate it (Diamond Shield) or any form of clear bra type protective covering for that matter on the front my motorhome. I also have it on my automobiles (3M Clear Bra). Yes, it's expensive and as some state a PITA to remove (actually, using steam will aid in the removal). I appreciate it due to the fact that it does mitigate the damage of road debris more so than many may recognize in the form of sand and other common road contaminants that without it will "sand blast" the front painted portion of the motorhome hence the reason manufacturers' install it to begin with.

-

Admittingly, I have not read all of the threads/replies to the OP's post...

Motorhome = 2017 Newmar 45DP / Spartan K3 / Cummins ISX15 (600hp)

Motorhome Length = 44.11" (w/installed Hydralift + Tow Vehicle OAL = 70' 3")

GCWR = 74,000 (we run at the mark, loaded).

Normal Average Interstate Hwy Cruise Speed = 65-MPH

Towing = Jeep SUV @ 5,000 + Garia LSV (Golf Cart on Lift) @ 2200 lbs (LSV + lift weight combined)

Cumulative Mileage Driven to date = 12,900 miles (still not "broken in")

Average MPG (all road types combined) = 6.7 MPG

-

It's true that "word on the street" is that the majority of lenders will not finance a RV (in this case, a Class A Motorhome) if >10 years in age - but my personal suspicion is that much depends on what it is (market value at time of purchase) and the individual's financial position, credit worthiness and liquidity.

(e.g. If one is in a position to place a large downpayment (i.e. securing let's say, 40-50% equity up front) or can demonstrate financial holdings/securities that can be bridged to such a loan (i.e. investments, home ownership, etc.) then some lenders may be willing to provide financing on the basis that the loan is less of a risk and further secured in terms of one's ability to repay it.

-

Planning the installation of ground effects LED light strips to surround the lower exterior of my motorhome and wondering if others here have done the same and can share information on the following;

1) if your installation includes the use of a RF remote to turn the LEDs on/off, where did you install it?, i.e. on the exterior of the motorhome such as in the electrical bay or inside the basement area, or on in the interior of motorhome, and how well would you describe how well the RF remote works (signal is good, fair, poor), same question applies if you installed colored LEDs and use a bluetooth/RF remote.

2) if you installed an in-line On/Off switch to control power to the LEDs where did you place it? inside the motorhome in or under the dash, in the basement area, etc.

2) did you direct connect to your motorhome's 12-volt DC current or use a 120 volts AC converter?

3) if you ran LED light strips around the entire underside of the motorhome, how many junction boxes/pole terminal connectors did you use to gather/consolidate the various power leads from each LED strip into a pair of common power wires (+/-) to tie into the converter?

4) have you had problems with the lights since installing them and if so, what were they?

Needless to say, I'm planning a DIY'er installation and have a fairly good view of how I need to do it, just felt that by asking other FMCA members here who've done their own installations (or had their's done), some additional insight would be helpful.

ps - please don't "bash"...Im doing a simple soft white installation that will simply serve to add additional exterior lighting downward toward the ground when parked/docked remotely. The LEDs will not be visible from the sides of the motorhome.

Any/All answers will help.

-

We make it a practice to take our coach out of storage and drive it for at least 25-30 miles once per month at a minimum most particularly during months when our use is limited (i.e. Nov-Mar). The practice also serves to ensure we get the engine/trans. up to full operating temp while also running the generator with a load on it. As well we also run the slides out/in, run the HVAC systems, move water through the plumbing including the Oasis/Hot water system, check tire pressures, brakes, air/hydraulics and observe for any abnormal conditions, etc..

Otherwise, we're averaging 12k miles per year actually using the coach which also drives us to ensure we're doing all recommended maintenance based upon both time and/or mileage (some of which we're doing a bit pre-maturely, i.e. oil changes, but feel its better to be proactive).

Overkill, some may say but I'm satisfied we're doing what's needed.

-

We worry about this subject too (both pests and rodents) particularly when garaging our MH in our storage building. Our storage building is large (60' x 100') and is located adjacent to open grassy "fields" so we perceive the risk of pest and rodents being high. To mitigate the risk, we;

1) employ a professional Pest Control company that comes monthly to re-load (8) rodent bait boxes and inspect/replace numerous sticky tack traps if needed as well as perform parameter pest control spraying. They charge us $35/month for these services which we think is reasonable.

2) ensure we never leave food waste/trash in our storage building, not even a empty paper coffee cup, etc. and we tend to remove all perishable and packaged foods from the MH when storing it (we do leave the canned goods). We also practice good MH-housekeeping and ensure the MH is properly vacuumed out and floors mopped with a disinfectant.

3) also have one of those ultrasonic electronic devices that emits a high frequency tone which we place underneath the MH and leave on when the MH is stored (not convinced these gadgets actually work but we go by the "more the better" in an attempt to avoid rodent and pest intrusion).

4) on occasion have also sprayed "peppermint" oil along the inside perimeter walls as well as around the MH tires which are positioned on dense rubber parking mats as a further "distraction", (another effort we don't know if using the oil works or not)

5) we do leave the MH connected to 50-amp shore power as well while in storage (which may/may not have an impact in terms mitigating pest/rodent)

Most importantly I suppose, we frequently look for tell-tale evidence of intrustion in the form of dead pest, rodent droppings, etc. both inside the MH and within the interior of our storage building. So far, we've seen little to no evidence which has been "good news" (particularly inside of the MH). As well, I typically visit the storage building once/twice a week just to check on the MH or to do other unrelated things in the building.

Note: after the 1st month of storing our unit two years ago I did find evidence of a rodent in the form of "a" single dropping on the roof of the coach wherein shortly afterwards, we commenced the pest/rodent control efforts listed above....since then, we've never seen "droppings" again so hopefully, we're doing what needs to be done to avoid any problems.

-

Something's always cooking around here

-

Our MH came equipped with a Sleep Number King mattress but better to our liking we added their CoolFit foam topper which made it all the more comfortable.

-

We have both wool and synthetic backed area rugs and use rug pads under each which are fibre and do not stick to or leave evidence of having been used on our tile floors.

-

Installing Ground Effects Surround Exterior LEDs

in Type A motorhomes

Posted · Report reply

Due to my having an OCD with respect to keeping my coach clean, I jack it up after every trip and scrub the belly pans and suspension. Not really. Its only because its still relatively new having purchased it 15 months ago albeit we did manage to over 6 months and 13,000 miles in the past 12 months. Planning now for next year where we'll leave in early March for what should be touring 8-months out west/northwest.