-

Content Count

4234 -

Joined

-

Last visited

-

Days Won

12

Posts posted by dickandlois

-

-

39 minutes ago, desertdeals69 said:The old inverter was a SW2000 watt Xantrex, pure sine wave. I haven't used a msw in 20 plus years. I also changed coaches 2 1/2 years ago. I have installed 3k inverters for years.

That is interesting ! Kind of skews the failure to the refrigerator. One would consider a 2000 W sine wave source large enough to power the refrigerator.

Thanks for your feedback !

Rich.

-

JT, the generator starting power comes from the chassis batteries, but very often the starter control circuit is power from the coach batteries.

So by running the engine - that put enough power in the 4 coach batteries to start the generator. The result you got when you tried the use the emergency starting circuit - makes me wounder if the battery connections and the condition of the 12 volt connections at the generator, along with basically dead coach batteries was caused by a combination of things.

Rich.

-

Carl, Keep your fingers crossed, tomorrow is party time. Hopping for none of mother natures light shows.

Rich.

-

DD69, you operated the same type refrigerator on an older inverter, that was most likely a modified sine wave and you have now up dated to a 3000 watt unit. Is the new one a pure sine wave inverter? 3000 Watt inverters where not vary common in your year coach.

Rich.

-

Rick, There are some items that need to be answered.

Your inverter and battery setup is big enough to power the unit, but does it use solid state control boards? Will the motor run on a modifier sine wave . Solid state circuits can have less then favorable operation on this type inverter and the RMS peak voltage average is below that of a pure sine wave inverter.

2. The new / second inverter has a built in automatic transfer switch. My idea is to connect the output of a 15 amp breaker in the coach load center (from the original refrigerator outlet) to the input of the new inverter. Then run the output of the inverter to the original refrigerator outlet.

Powering a second inverter from a MS unit could create some interesting harmonics in the line powering the refrigerator. The Basic design is not setup for the scenario you are contemplating. Could generate some unwanted heat in both the inverter and the fridge. If you have the needed test equipment and can construct a test setup to test your idea - with the ability to return the items. It would be interesting to know the result.

Rich.

-

kwl0525,

The coach has 34,500 miles on it and I'm the 2nd owner. The mileage on the coach, puts the fuel lift pump in the range for the OEM fuel pump to fail !!!!

If you do not have fuel pressure gauge set up Have it checked !!!!! Bad lift pumps and cause serious damage to the injector pumps. Fuel flow and pressure is critical. The fuel is used to keep the injector pump cool.

Rich.

-

dpeebles doing a test.

-

kwl0525, You mentioned that the one option is Phenolic, that is a very rigid plastic, more pron to cracking and with the possibility of high temps when descending a steep grade could heat things up and a dragging brake pad would do the same . Plastic and steel have totally different expansion cofficiants - that would tend to skew me towards the metal pistons, but I have never used calipers with Phenolic pistons.

I fear the caliper pins hanging up more then any other part of the caliper ! If the coach sets for extended periods - they need more attention then the pistons.

Rich.

-

2 hours ago, kwl0525 said:Rich - The 2 fuel filters were changed 2 years ago. I need to look again to see if there is a 3rd one lurking somewhere. Coolant level is good and it was changed at the same time as the fuel filters. I don't know when the radiator and CAC were cleaned, but they appear to be in good shape and aren't gunked up with oily grime buildup.

Yes, the engine light only comes on when the exhaust brake kicks in and the unit downshifts, which immediately increases the RPMs. Once the RPMs reduce, the engine light goes out.

I still need to check out your other suggestions.

Thanks!

Brett, posted some good information just prior to me-so look it over.

When I asked how old the fuel lift pump was, maybe it would have been better to ask how many miles are on the coach and are you a second owner?

That third filter is like 30 micros and they pick up the bigger stuff. The common problem is loos of power, but it could easily cause the engine to surge because of a reduced fuel flow and Cummings fuel pumps can be very temperamental.

Brett, mentioned calling them regarding RPM items and a Call to Freightliner will get you an engine serial number. With that and they also would have installed that 3rd. filter, because it is not mounted on the engine.

Rich.

-

Peter, Your information is a little confusing. Driveshaft center carrier bearing, on this side of the pond are in the driveshaft of front engine vehicles. because of the length of the shaft.

You coach series is XC-21-RDX. The R is for rear engine and the drive shaft is not that long. The 21 means it is a 21,000 LB. chassis

So are you asking about a differential (pumpkin) Drive shaft carrier bearing inside that gear assembly or the Axle bearings ?

The internal bearings in many cases have a number stamped in them and that might help, but I would not go there until all other possibilities are exhausted.

In that case you need the parts for the differential. They are made by a different company that supplies them to the chassis builder as an Assembly.

By companies like Rockwell and Meritor. There should be some numbers on the assembly on a tag or a casting number(s)

Rv Chassis like your are know as medium duty chassis.

Rich.

-

There has been a change at Magnum Power.

The old information link was http://www.magnumenergy.com/service/servicecenters-us.htm,

You will be directed to the new link, but they do not list service centers at the new sight.

The New information link is. http://www.magnum-dimensions.com/document-library

The documentation at the new link is extensive, but it looks like all repair work at just one location. However! I'm not sure this is just for warranty work or all repair work at this time.

Rich.

-

Joe, Do you keep a soft blow hammer in the bay to start the fuel pump? LOl

just could not pass it up!

Did you forget to connect the water in fuel connection? or is it no longer in use?

Rich.

-

2 hours ago, rsbilledwards said:Could it be that the low cut off voltage is not low enough to prevent interruption. I had a similar problem last winter but the unit would come back on after battery voltage came back up. By that time implements would have shut off and have to be turned back on.

Bill, I just added info. regarding the factory cutoff voltage level. Factory level is set at 11.00 volts, but is menu adjustable by the user.

However ! There is a preset level of 5 watt load and lower and the inverter will power down and from my experience these system require a solid load of 5 watts to restart. They will not start when seeing a logic control board or other device below that level. I have set my Xantrex unit so it will stay on - even though the unit will use some power while in the idle state.

Rich.

-

2 hours ago, manholt said:I'm thinking you have the same problem as FIVE had...Electrical, page 14. June 2016.

Carl, you could be onto something! New coaches have some bugs and a loose ground could be the issue. The item that keeps me scratching my hear is - only shuts down when on the road and the inverter is making power as far as I understand the OP. Lyle posted this though.

Posted 9 hours ago Went off again last night while plugged into shore power and no fault codes mentioned.

The factory battery level cutoff voltage is set at 11.00 volts. The inverter will shut down. With the coach connected to shore power unlikely issue.

The inverter is set to power down if the load drops below 5 watts. This is a possible issue - can it be set to not turn off with little or no load? One might use a small light or other device that requires a constant load of 5 watts or more, to see if the inverter stops operating when the refrigerator or other loads drop below the low level set point .

Lyle, you did not mention if the refrigerator warmed up - shore power was connected over night and the refrigerator should have continued to work with power supplied via the bypass relay circuit in the inverter.

The manual mentions the the inverter should restart after an over temp event / when the temperature drops below a preset level - No info on what they set that temperature at.

After a overload event happens one needs to manually restart the inverter. Think I,m reading the manual correctly ! I have no information on the primary wiring and how the EMS system that sheds loads while on shore power would work or interact with the inverter supplying power ?

So the search goes on..... Not every piece of equipment is created equal. If the common ground is good at all points, then I would start wondering if there is something going on internally with the unit ??? They do have a limited warranty them for 3 years.

Rich.

There is a need for me to upgrade my organic microprocessor. Think I'm running on an older 8088 and updating to an I - 5 might help. Brett keeps telling me I need some cranial work. LOL

-

Tim, Welcome to the learning curve we have all been on and in most cases still are.

No problem and the thing is you asked and offering our thoughts and time go with our interest to help.

Regarding those battery cables, a number of us have also missed things. LOL

Safe travels and thanks for offering the apologies.

Rich.

-

Lyle, been fallowing this thread and wondered if this issue has come up when the temperatures went up? Any issue when the temps where lower ?

What items are you running that require 12 volts while driving?

Hooked up to shore power - they are in bypass mode on the road and making power, they generate higher temperatures.

The thought I have regarding the Inverter shutting down. This summer has been rather warm and inverters need to have enough air movement to keep from over heating.

They are often mounted at the top of a closed bay where the heat is greater an air exchange is limited. There is a strong possibility that it is a terminal issue shutting it down.

Rich.

-

Tim, The Vintage coaches - in you coaches year used F usable Links, that where connected between the Large gauge wire terminals and the relay / solenoids coil that activates them when the switch supplies the ground point.

These links burn open and leave no visible indication of them failing, They are gray in color and are very supple - Silicon coated wire. One needs to check them with an ohm meter to see if they still are good.

In the picture there are 2 large high amperage fuses the supply the system fuses boxes - that might have failed.

If the links or the high amperage fuses have failed then, there is a good chance that something in the system shorted out, failed or a 12 volt wire made a connection to ground due to loose terminal connection.

I have no wiring drawing that pictures the control wiring - all I have are the drawing for the heavy gauge wiring circuits.

Rich.

You did offer this little tidbit. There will be a 12 volt terminal lug in that line - ether at the fuse panel or somewhere close - in most cases, as they run the cables from there source(in this case the manual disconnect switch and the post / that feeds power to the main fuse panel !!!

In the electrical panel below the driver's side window is a terminal with a large cable labeled "House" and when I hook up my meter to this, I get no reading. I am assuming this cable is the same one that exits the battery box in the rear (?) in which case it should have 12.6v but it does not.

-

6 minutes ago, manholt said:There is also a CB on your generator.

Carl, Looking at some Monaco drawings and the start circuit / to engage the generator is powered from the house 12 volt system from some where and that system is totally dead from the information offered by the OP information.

Rich.

-

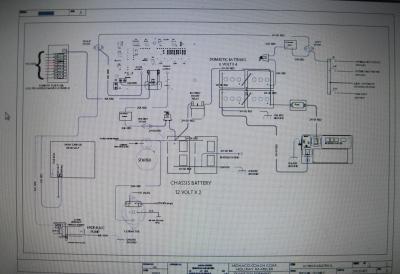

Tim , this is a picture of a Monaco 12 volt circuit the should be real close to your system.

It sure looks like the generator starting power goes through one of the disconnect switches and a disconnect relay for your year coach. Top left corner of the image.

House power, so there could be a coil fuse issue, like Richard mentioned. I will look over the manual more and see if there is a drawing that pictures the coil circuit wiring from the salesmen switch.

This was taken from a secure file so I could not create a PDF file image. Hope you have a way to enlarge if needed.

Rich.

-

Thanks for the feedback Tim !!!

There is a strong possibility that the problem is in your 12 volt fuse panel !

If you feel comfortable, disconnect the ground connection(s) from the coach battery bank, remove the 12 volt panel cover and check for loose connections at the screw terminals for both the 12 volts and the grounds .

Note. because of the close proximity of the 120 volt power and the DC power it would be wise to disconnect from shower power !!!

no interior lights, porch light, etc. 12 volts - microwave, 120 volts ???

The inverter should power the microwave from shore power. Possible tripped GFI, open circuit breaker at the inverter output. No power from the inverter when running from the coach batteries, would indicate an issue in the same items mentioned.

Rich.

-

Brett mentioned getting the Generator started. Is you generator on a slide out ? You should have 12 pulse volts at the battery connection on the generator.

Rich.

19 minutes ago, wolfe10 said:Rich,

?? But, will the large gauge wire to the generator starter run through the salesman switch??

No !!! it generally connects directly to the chassis batteries and as I mentioned - there should be 12 volts at the connection point on the generator.

No power there then got a feeling that there is a loose ground or supply cable at the generator or right at the battery, very little in between the 2 points. Note They use the Chassis for the ground between the generator and batteries - 2 to 3 possible locations for interrupting the ground side.

We know that he has 12 volts at the house battery - but not what is at the chassis / engine batteries though, Good Point thought !!!

Do you have power to the engine ignition switch ? A bad chassis battery could pull down the house batteries enough to bring them down !!!! when the cross connect is attempted with the assist switch.

Rich.

-

Tim, Have you inadvertently turned off the power at the salesmen switch, generally right in the entry and is easily bumped.

Rich.

-

The power for the jacks is supplied from the chassis batteries. Through the ignition switch in most cases.

Might look in the front left bay of the coach, think there is a fuse panel there on your coach that powers the leveling system, but With the ignition switch in the off position - do the leveling system lights come on? If not then leave the Ign.. sw. in the off position for 10 min. or so then try them again. Transmission in Neutral - park brakes set.

Reading some information and I think you have an older Power Gear leveling system that could include this feature.

AUTOMATIC SAFETY SHUTOFF FEATURE

If the touch panel is left on and inactive for four minutes it will shut off automatically. To reset the system the coach ignition must be turned off, then back on.

Take a look at this link, look like your control panel or close to it?

https://www.lci1.com/assets/content/support/drawings/pg-82-L0140-00.pdf

Rich.

-

Kay, I think his system uses the R-22 - could be wrong ?

Rich.

Generator starting

in Electrical

Posted · Report reply

Have you got a crystal Ball ?

That same thought crossed my mind, but not having the full wiring drawings it is one of those unknowns for now!

I will be off line for a few days starting tomorrow not because I want to it is a necessity. So time is not free to dig into it for now.

Rich.

Looks like Bill has a handle on it and I would go along wit Bill , that it is by directional .